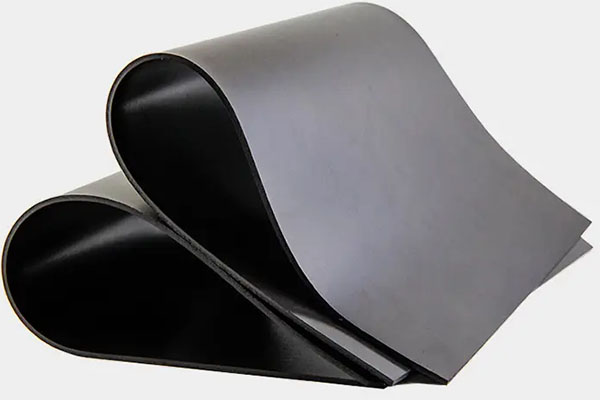

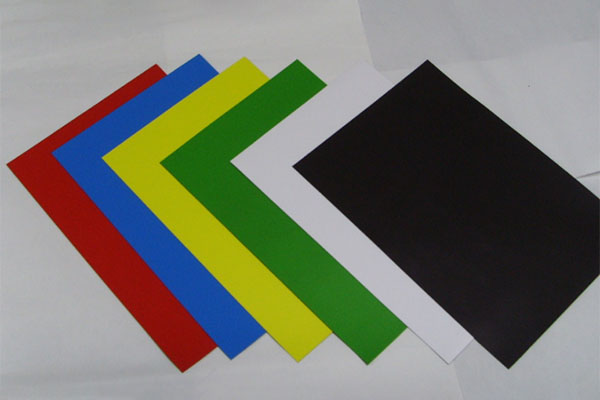

Ka dib markii la farsameeyo, qaabku waa dabacsan yahay, laastikada, iyo laablaaban karo, qaabkana waa la gooyn karaa iyadoo loo eegayo cabbirka loo baahan yahay, sidoo kale waxaa lagu dabooli karaa PVC, koolo, iyo saliid UV iyadoo loo eegayo shuruudaha gaarka ah ee macaamiisha.

Tijaabada waxqabadkeeda guud ahaan waxaa ka mid ah muuqaalka, cabbirka, guryaha magnetic, polarity magnetka, qallafsanaanta, cuf-jiidka gaarka ah, xoogga xajinta, caabbinta gabowga, waxqabadka wareegga.

Faa'iidooyinkeedu waxay ku jiraan joogteynta wanaagsan, saxnaanta cabbirka sare;saameyn wanaagsan iyo caabbinta gariir, ma fududa in la jebiyo;cuf-jiid yar oo ku habboon miisaanka khafiifka ah ee qalabka iyo mashiinka oo dhan;waxa lagu soo saari karaa birlab leh shucaac buuxa (full radiation) jihada, waxaana lagu soo saari karaa noocyo kala duwan oo magnets ah sida qaabab dhaadheer iyo kuwo dhuuban, marka shaqada ka dib sida maran, goyn, feero iyo foorarsi si fudud ayaa loo samayn karaa .

Khasaaraha uu leeyahay ayaa ah in magnetism-ku uu aad u daciifo, xooggii birlabkuna uu bilaabo inuu hoos u dhaco 100 ° C, ka sokow, magnetka caagga ah waxaa ku jira walxo badan oo bir ah sida neodymium iyo birta, kuwaas oo noqon doona daxal iyo daxal hawada hawada. Sifooyinka heerkulku aad bay u liitaan, wayna fududahay in la jeexjeexo.

Waxaa inta badan loo adeegsadaa shaabado adag oo albaabbada qaboojiyaha ah, armaajooyinka jeermiska dila, armaajooyinka jikada, alaabta carruurtu ku ciyaarto, qalabka wax lagu qoro, xayaysiisyada, mishiinnada marawaxada qaboojiyaha kombuyuutarka, matoorada sahayda hawo qaboojinta, matoorada wadida daabacaadda, VCD iyo matoorada DVD-ga, dabaysha DC ee aan burushka lahayn marawaxadaha, Albaabka magnetic, qurxinta, daryeelka caafimaadka joodariyaasha magnetic, ulo magnetic, calaamadda darawalka ku meel gaadhka ah ee baabuurta rakaabka,Daaynta rakibaadda wiishka (dhammaan wiishashku waxay isticmaalaan xaashida daawaynta), Qalabka xafiisyada iyo alaabta cusub (ku habboon alaabta xidhiidhka dadweynaha).

Astaamaha Jirka ee Magnet-ka caagga ah

| Heerkulka Curie (℃) | 100 |

| Heerkulka shaqada ee ugu badan (℃) | -40-80 |

| Hv (MPa) | 33-38D |

| Cufnaanta (g/cm3) | 3.6-3.8 |

Socodka wax soo saarka

Baaritaanka Agabka

Isku dhafka walxaha

Banburying

Burburinta

Qalabaynta Bannaanka

Kormeerka iyo Baakaynta

Tusiyaha waxqabadka walxaha ee magnet-ka caagga ah

| Qaabka | Nooca Alaabta | Waxqabadka Magnetic | Hantida Jirka | ||||||||||

| Br | BHc | Hcj | BHmax | Xooga Jilicsan | Adag | Cufnaanta | Heerkulka | ||||||

| mT | Gs | KA/m | Oe | KA/m | Oe | KJ/m³ | MGOe | kg/c㎡ | A | g/cm³ | ℃ | ||

| DMS001 | Xarigga magnetic extrusion isotropic | 140-180 | 1400-1800 | 105-130 | 1320-1635 | 160-238 | 2010-3000 | 4-6.4 | 0.5-0.8 | ≥20 | ≥90 | 3.6-3.8 | -40 ~ 85 |

| DMS002 | Semi-anisotropic extrusion magnetic | 180-210 | 1800-2100 | 130-151 | 1635-1900 | 175-286 | 2200-3600 | 6.4-8.8 | 0.8- 1. 1 | ≥20 | ≥90 | 3.6-3.8 | -40 ~ 85 |

| DMS003 | Magnet-ka caagga ah ee isku-dhafan ee isotropic | 180-220 | 1800-2200 | 111-143 | 1400-1800 | 143- 191 | 1800-2400 | 5.6-8.8 | 0.7- 1. 1 | ≥20 | ≥95 | 3.6-3.8 | -40 ~ 85 |

| DMS004 | Xarigga magnetic extrusion anisotropic | 210-250 | 2100-2500 | 151-179 | 1900-2250 | 191-319 | 2400-4000 | 8.8- 12 | 1. 1- 1.5 | ≥20 | ≥90 | 3.6-3.8 | -40 ~ 85 |

| DMS005 | Semi-anisotropic colendering caag magnet | 220-240 | 2200-2400 | 128-151 | 1600-1900 | 159-207 | 2000-2600 | 8.8- 11.2 | 1. 1- 1.4 | ≥20 | ≥95 | 3.6-3.8 | -40 ~ 85 |

| DMS006 | Anisotropic colendering caag ah | 240-270 | 2400-2700 | 151-179 | 1900-2250 | 191-238 | 2400-3000 | 11.2- 13.6 | 1.4- 1.7 | ≥20 | ≥95 | 3.6-3.8 | -40 ~ 85 |

| DMS007 | Xarigga mashiinka korantada 500# | 240-270 | 2400-2700 | 151-179 | 1900-2250 | 191-238 | 2400-3000 | 11.2- 13.6 | 1.4- 1.7 | ≥15 | ≥95 | 3.6-3.8 | -40 ~ 85 |

| DMS008 | Xarigga mashiinka korantada 300# | 240-265 | 2400-2650 | 151-179 | 1900-2250 | 191-238 | 2400-3000 | 11.2- 13.2 | 1.4- 1.65 | ≥15 | ≥95 | 3.6-3.8 | -40 ~ 85 |

Muujinta Sawirka

-

Assemblies Magnet leh NdFeB, SmCo, AlNiCo iyo ...

-

Block NdFeB, guud ahaan waxaa lagu dabaqay moto toosan...

-

Wareega NdFeb, guud ahaan lagu dabaqay electroacou...

-

Qaababka kale ee NdFeB, sida qaabka rootiga, daloolka

-

Qaybta NdFeB, guud ahaan lagu dabaqay koronto ...

-

Garaac NdFeB, oo guud ahaan loo isticmaalo cod-baahiyaha