Ka sokow, magnets SmCo waxay leeyihiin astaamo kale:

Waxqabad la isku halayn karo: Magnets-yada SmCo aad bay ugu adkaysanayaan demagnetization-ka taasoo ka dhigaysa kuwo lagu kalsoonaan karo degaanno badan.

Daxalka iyo iska caabinta oksaydhka: Maaddaama maadada birta ay ku yar tahay ee walxaha isku dhafan, magnets SmCo waxay leeyihiin iska caabin daxalka oo aad u fiican.Si ka duwan NdFeB, magnets SmCo uma baahna koronto-samaynta.

Dejinta heerkulka: SmCo waxay ku hayn kartaa xooggeeda birlabeed heerkul sare (249-300 ℃) iyo heerkul aad u hooseeya (-232 ℃).

Walxaha jajaban: Marka lagu jiro sintering, maaddadu waxay noqon kartaa mid jajaban, sababtoo ah way jajaban tahay oo sahlan tahay in la dillaaco, farsamaynta ayaa leh xaddidaad, taas oo hababka habraaca dhaqameed aan la shaqeyn karin.Si kastaba ha ahaatee, waa la dhulka dhigi karaa, laakiin kaliya haddii qadar badan oo qaboojiye ah la isticmaalo.Taasi waa sababta oo ah qaboojiyaha ayaa yarayn kara khatarta dabka ee dillaaca kulaylka iyo boodhka shiididda oksaydhaysan.

Codsiyada:

1. Matoorada PM-dhamaadka sare.Matoorada PM-ka ee caadiga ah waxay isticmaalaan magnets ferrite ama magnets NdFeB.Laakin meelaha heerkulku ka sareeyo 200 ℃ ama qul qulka cooshka uu weyn yahay, kaliya matoorada SmCo PM ayaa awood u leh.

2. Qalabka korantada ee nidaamyada cod-baahiyeyaasha-dhamaadka sare.

3. Nidaam qalab oo aad loogu kalsoon yahay.Qalab badan oo loo isticmaalo hawada, duulista, caafimaadka iyo goobaha kale waa inay isticmaalaan magnets joogto ah ee SmCo si loo hubiyo isku halaynta sare iyo badbaadada qumman.

4. Raadaarka aadka muhiimka u ah iyo hababka isgaarsiinta, tiro badan oo ah tuubooyinka mowjadaha socdaalaya, magnetrons, tuubooyinka eryanaya, tuubooyinka hirarka, gyrotrons iyo qalabyada kale ee korontada ayaa loo isticmaalaa, iyo SmCo magnets waxay sameeyaan alwaaxyo elektaroonik ah oo ku socda socodka wadada loo qoray.

5. SmCo magnetic soosaarayaasha ceelasha qoto dheer ka hooseeya 3000 mitir, iyo SmCo magnetic drive (pump) ee deegaanka heerkulka sare ee 200 ℃.

6. Madaxa nuugista magnetic, kala-soocida birta, birta birta, NMR, iwm.

Liiska Fasalka SmCo Magnet

| Qalab | No | Br | Hcb | Hcj | (BH) ugu badnaan | TC | TW | (Br) | Hcj | ||||

| T | |KGs | KA/m | KOe | KA/m | KOe | KJ/m3 | MGOe | ℃ | ℃ | %℃ | %℃ | ||

| 1:5 SmCo5 (Smpr) Co5 | YX-16 | 0.81-0.85 | 8.1-8.5 | 620-660 | 7.8-8.3 | 1194-1830 | 15-23 | 110-127 | 14-16 | 750 | 250 | -0.050 | -0.30 |

| YX-18 | 0.85-0.90 | 8.5-9.0 | 660-700 | 8.3-88 | 1194-1830 | 15-23 | 127-143 | 16-18 | 750 | 250 | -0.050 | -0.30 | |

| YX-20 | 0.90-0.d4 | 9.0-9.4 | 676-725 | 8.5-9.1 | 1194-1830 | 15-23 | 150-167 | 19-21 | 750 | 250 | -0.050 | -0.30 | |

| YX-22 | 0.92-0.96 | 9.2-9.6 | 710-748 | 8.9-94 | 1194-1830 | 15-23 | 160-175 | 20-22 | 750 | 250 | -0.050 | -0.30 | |

| YX-24 | 0.96-1.00 | 9.6-10.0 | 730-770 | 9.2-9.7 | 1194-1830 | 15-23 | 175-190 | 22-24 | 750 | 250 | -0.050 | -0.30 | |

| 1:5 SmCo5 | YX-16S | 0.79-0.84 | 7.9-8.4 | 612-660 | 7.7-83 | ≥ 1830kii | ≥ 23 | 118-135 | 15-17 | 750 | 250 | -0.035 | -0.28 |

| YX-18S | 0.84-0.89 | 8.4-89 | 644-692 | 8.1-8.7 | ≥ 1830kii | ≥ 23 | 135-151 | 17-19 | 750 | 250 | -0.040 | -0.28 | |

| YX-20S | 0.89-0.93 | 8.9-9.3 | 684-732 | 8.6-92 | ≥ 1830kii | ≥ 23 | 150-167 | 19-21 | 750 | 250 | -0.045 | -0.28 | |

| YX-22S | 0.92-0.96 | 9.2-9.6 | 710-756 | 8.9-95 | ≥ 1830kii | ≥ 23 | 167-183 | 21-23 | 750 | 250 | -0.045 | -0.28 | |

| YX-24S | 0.96-1.00 | 9.6-10.0 | 740-788 | 9.3-9.9 | ≥ 1830kii | ≥ 23 | 183-199 | 23-25 | 750 | 250 | -0.045 | -0.28 | |

| 1:5 (SmGd) Co5 | LTc(YX-10) | 0.62-0.66 | 62-6.6 | 485-517 | 6.1-6.5 | ≥ 1830kii | ≥ 23 | 75-8A | 9.5-11 | 750 | 300 | 20-100 ℃ +0.0156% ℃ 100-200 ℃ +0.0087% ℃ 200-300℃ +0.0007%℃ | |

| Ce(CoFeCu)5 | YX-12 | 0.7Q-0.74 | 7.0-7.4 | 358-390 | 4.5-4.9 | 358-478 | 4.5-6 | 80-103 | 10-13 | 450 | 200 | ||

| Sm2 (CoFeCuZr)17 | YXG-24H | 0.95-1.02 | 9.5-10.2 | 692-764 | 8.7-9.6 | ≥ 1990kii | ≥ 25 | 175-191 | 22-24 | 800 | 350 | -0.025 | -0.20 |

| YXG-26H | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | ≥ 1990kii | ≥ 25 | 191-207 | 24-26 | 800 | 350 | -0.030 | -0.20 | |

| YXG-28H | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | ≥ 1990kii | ≥ 25 | 207-220 | 26-28 | 800 | 350 | -0.035 | -0.20 | |

| YXG-30H | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥ 1990kii | ≥ 25 | 220-240 | 28-30 | 800 | 350 | -0.035 | -0.20 | |

| YXG-32H | 1.10-1.13 | 11.0-11.3 | 812-860 | 10.2-10.8 | ≥ 1990kii | ≥ 25 | 230-255 | 29-32 | 800 | 350 | -0.035 | -0.20 | |

| YXG-22 | 0.93-0.97 | 9.3-97 | 676-740 | 8.5-93 | ≥ 1453 | ≥ 18 | 160-183 | 20-23 | 800 | 300 | -0.020 | -0.20 | |

| YXG-24 | 0.95-1.02 | 9.5-10.2 | 692-764 | 87-9.6 | ≥ 1433 | ≥ 18 | 175-191 | 22-24 | 800 | 300 | -0.025 | -0.20 | |

| YXG-26 | 1.02-1.05 | 10.2-10.5 | 748-796 | 9.4-10.0 | ≥ 1433 | ≥ 18 | 191-207 | 24-26 | 800 | 300 | -0.030 | -0.20 | |

| YXG-28 | 1.03-1.08 | 10.3-10.8 | 756-812 | 9.5-10.2 | ≥ 1433 | ≥ 18 | 207-220 | 26-28 | 800 | 300 | -0.035 | -0.20 | |

| YXG-30 | 1.08-1.10 | 10.8-11.0 | 788-835 | 9.9-10.5 | ≥ 1453 | ≥ 18 | 220-240 | 28-30 | 800 | 300 | -0.035 | -0.20 | |

| YXG-32 | 1.10-1.13 | 11.0-11.3 | 812-860 | 10.2-10.8 | ≥ 1433 | ≥ 18 | 230-255 | 29-32 | 800 | 300 | -0.035 | -0.20 | |

| YXG-26M | 1.02-1.05 | 10.2-10.5 | 676-780 | 8.5-9.8 | 955-1433 | 12-18 | 191-207 | 24-26 | 800 | 300 | -0.035 | -0.20 | |

| YXG-28M | 1.03-1.08 | 10.3-10.8 | 676-796 | 8.5-10.0 | 955-1433 | 12-18 | 207-220 | 26-28 | 800 | 300 | -0.035 | -0.20 | |

| YXG-30M | 1.08-1.10 | 10.8-11.0 | 676-835 | 8.5-10.5 | 955-1433 | 12-18 | 220-240 | 28-30 | 800 | 300 | -0.035 | -0.20 | |

| YXG-32M | 1.10-1.13 | 11.0-11.3 | 676-852 | 8.5-10.7 | 955-1433 | 12-18 | 230-255 | 29-32 | 800 | 300 | -0.035 | -0.20 | |

| YXG-24L | 0.95-1.02 | 9.5-10.2 | 541-716 | 6.8-9.0 | 636-955 | 8-12 | 175-191 | 22-24 | 800 | 250 | -0.025 | -0.20 | |

| YXG-26L | 1.02-1.05 | 10.2-10.5 | 541-748 | 6.8-9.4 | 636-955 | 8-12 | 191-207 | 24-26 | 800 | 250 | -0.035 | -0.20 | |

| YXG-28L | 1.03-1.08 | 10.3-10.8 | 541-764 | 6.8-9.6 | 636-955 | 8-12 | 207-220 | 26-28 | 800 | 250 | -0.035 | -0.20 | |

| YXG-30L | 1.08-1.15 | 10.8-11.5 | 541-796 | 6.8-10.0 | 636-955 | 8-12 | 220-240 | 28-30 | 800 | 250 | -0.035 | -0.20 | |

| YXG-32L | 1.10-1.15 | 11.0-11.5 | 541-812 | 6.8-10.2 | 636-955 | 8-12 | 230-255 | 29-32 | 800 | 250 | -0.035 | -0.20 | |

| (SmEr)2 (CoTM)17 | LTC (YXG-22) | 0.94-0,98 | 9.4-9.8 | 668-716 | 8.4-9.0 | ≥1433 | ≥18 | 167-183 | 21-23 | 840 | 300 | -50-25 ℃ +0.005% ℃ 20-100 ℃ -0.008% ℃ 100-200 ℃ -0.008% ℃ 200-300 ℃ -0.011% ℃ | |

| Qalabka jirka ee Samarium Cobalt | ||

| Halbeegga | SmCo 1:5 | SmCo 2:17 |

| Heerkulka Curie(℃) | 750 | 800 |

| Heerkulka shaqada ugu badan (℃ | 250 | 300 |

| Hv(MPa) | 450-500 | 550-600 |

| Cufnaanta (g/cm³) | 8.3 | 8.4 |

| Isku-dhafka heerkulka Br (%/℃) | -0.05 | -0.035 |

| Isku-dhafka heerkulka iHc (%/℃) | -0.3 | -0.2 |

| Xoog xajin (N/mm) | 400 | 350 |

| Xoog jebinta leexleexa (N/mm) | 150-180 | 130-150 |

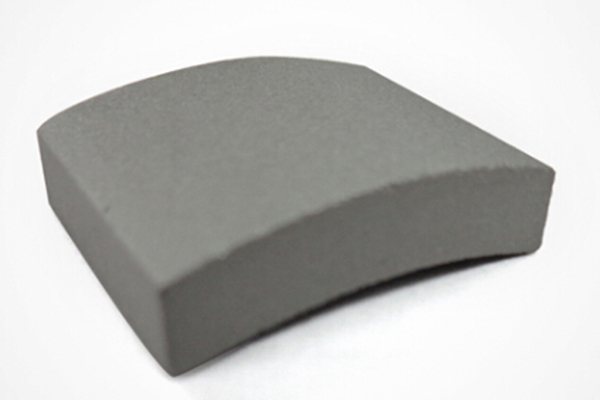

Codsiga

Magnet SmCo waxaa si weyn loogu isticmaalaa hawada, matoor heerkul sare u adkaysta, qalabka microwave, isgaarsiinta, qalabka caafimaadka, qalabka iyo mitir, qalabka kala duwan ee gudbinta magnetic, dareemayaal, processor magnetic, gariiradda cod matoorada iyo wixii la mid ah.

Muujinta Sawirka

-

Codsashada Wareegga NdFeb ee Electroacoustic

-

Sahami Cabbirrada Kala Duwan ee Magnets Ferrite ee xidhan

-

Qaybta NdFeB Magnets ee Matoorada Korontada: Sare ...

-

Qiimaha Warshada ee Kala badh giraanta NdFeB Magnet Xoog leh...

-

Iibiyeyaasha Jumlada ee Tusaalaha Bilaashka ah ee N52 Block Neod...

-

Xulasho weyn oo loogu talagalay Neodymium Magnet Awood leh...