Codsiga: Si ballaaran loo isticmaalo matoor aan burush lahayn, matoor warshadeed magnet joogto ah, matoor dhar ah, mooto baabuur, motor toos ah magnet joogto ah, motor toosan, qaboojiyaha matoor, qalabka makaanikada matoorka joogtada ah, koronto dhaliyaha badda, matoor magnet joogto ah, matoor firfircooni magnet joogto ah , macdanta birta magnet joogto ah, matoorka isku-xidhka, kiimikaad magnetka joogtada ah, motor wadista EV, mishiinka bamka, mishiinka EPS, dareenka iyo aag kale.

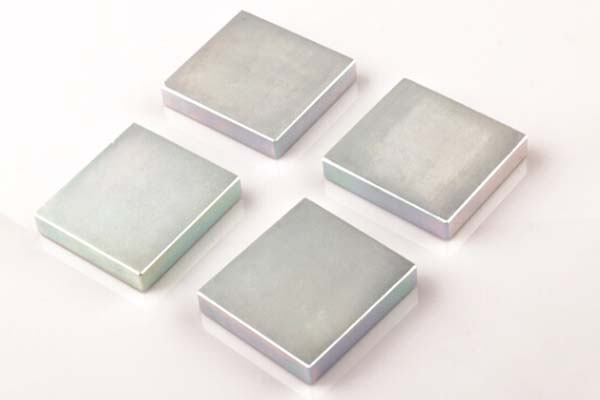

Product customized: magnet dhamaantood waa la habeeyey, dhererku wuxuu noqon karaa 0.5mm-200mm, width ka 0.5mm-150mm, dhumucdiisuna waxay ka 0.5mm-70mm, kaas oo buuxin kara shuruudaha macaamiisha intooda badan.

Dahaarka: NdfeB magnet waa ay fududahay in la oksijiyeeyo, sidaa darteed caadi ahaan waxay u baahan tahay dahaar, dahaarka inta badan laga isticmaalo suuqa sida:

1. Dajinta ZN (nooc ka mid ah daahan biraha, tijaabada buufinta milixdu waxay gaari kartaa saacadaha 24-48, waxqabadka qiimaha sarreeya, sidaas darteed waa mid ka mid ah xulashada ugu fiican ee macaamiisha intooda badan).

2. NICUNI (nooc ka mid ah daahan birta ah, tijaabada buufinta milixdu waxay gaari kartaa saacadaha 48-72, waxqabadka kharashka ayaa ka sarreeya ZN, laakiin weli si aad ah ayaa loo isticmaalaa suuqa xaaladda shirku waa mid adag, shuruudaha iska caabinta daxalka alaabta ee macaamilka ayaa kara dooro).

3. Epoxy (daahan aan biraha ahayn, korantada aan magnetka ahayn, waxay yarayn kartaa lumitaanka mootada eddy hadda, tijaabada buufinta milixda waxay gaari kartaa saacadaha 72-96, qiimo ka sarreeya ZN dahaarka NICUNI.)

4. Dahaarka kale ee sidoo kale la isticmaalay: Phosphate, Sn, Au, Ag, Parylene iyo wixii la mid ah

Dulqaad: Caadiyan dulqaadkayaga magnetku waa +/- 0.05mm daahan ka dib.

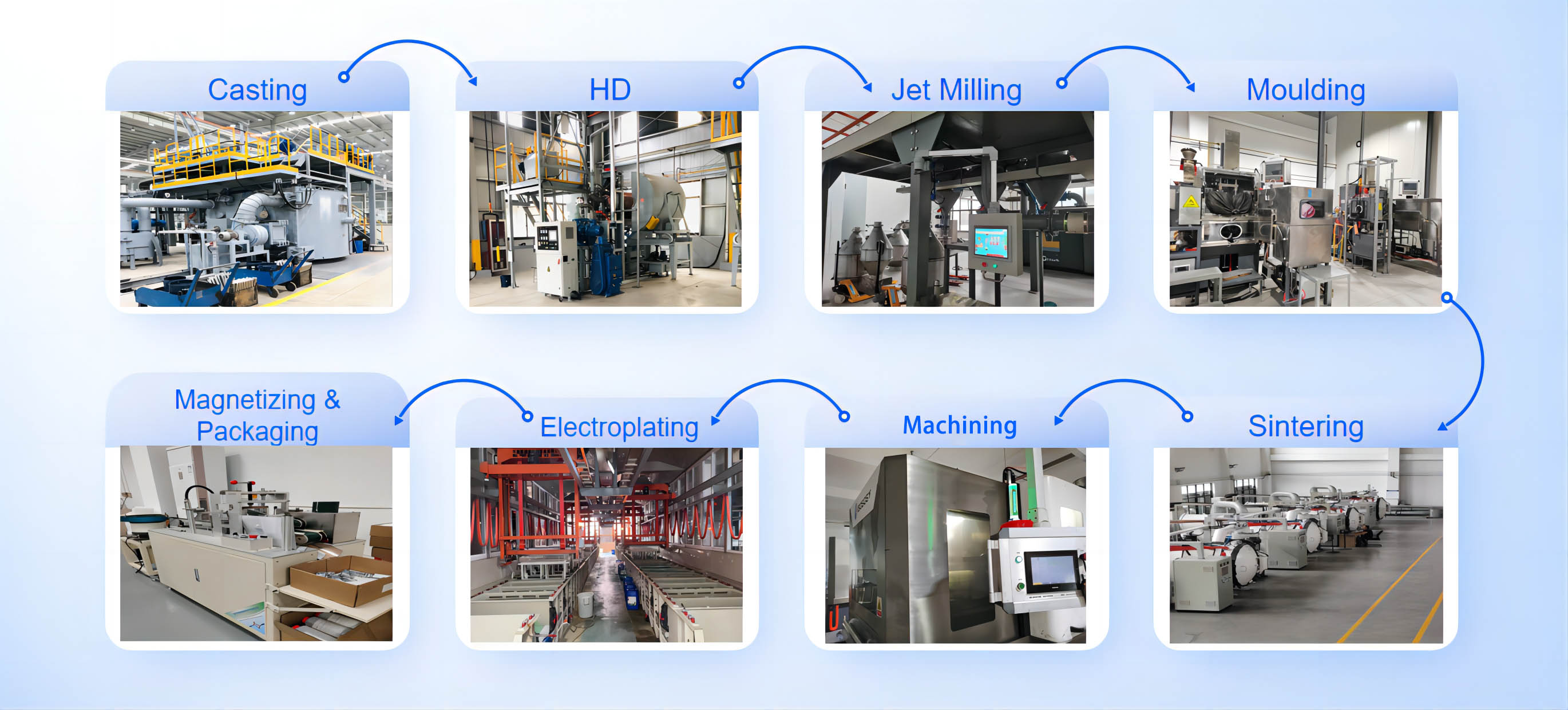

Habka Waxsoosaarka NdFeB

Hordhac Dahaarka

| Dusha sare | Dahaarka | Dhumucda μm | Midabka | Saacadaha SST | Saacadaha PCT | |

| Nikkel | Ni | 10 ilaa 20 | Silver dhalaalaya | >24~72 | >24~72 | |

| Ni+Cu+Ni | ||||||

| Nickel madow | Ni+Cu+Ni | 10 ilaa 20 | Madow dhalaalaya | >48~96 | >48 | |

| Cr3+ Zinc | Zn C-Zn | 5~8 | Brighe Blue Midabka dhalaalaya | >16~48 >36~72 | --- | |

| Sn | Ni+Cu+Ni+Sn | 10 ilaa 25 | Silver | >36~72 | >48 | |

| Au | Ni+Cu+Ni+Au | 10 ilaa 15 | Dahab | >12 | >48 | |

| Ag | Ni+Cu+Ni+Ag | 10 ilaa 15 | Silver | >12 | >48 | |

| Epoxy | Epoxy | 10 ilaa 20 | Madow/Cawlan | >48 | --- | |

| Ni+Cu+Epoxy | 15 ilaa 30 | >72~108 | --- | |||

| Zn+Epoxy | 15 ilaa 25 | >72~108 | --- | |||

| Dareenka | --- | 1~3 | Cawlan madow | Ilaalinta ku meel gaadhka ah | --- | |

| Fosfate | --- | 1~3 | Cawlan madow | Ilaalinta ku meel gaadhka ah) | --- | |

Astaamaha Jirka

| Shayga | Halbeegyada | Tixraaca Qiimaha | Unug |

| Kaaliyaha Magnetik Guryaha | Isku-dhafka Heerkulka La-noqon karo ee Br | -0.08--0.12 | %/℃ |

| Isku-dhafka Heerkulka La-noqon karo ee Hcj | -0.42~-0.70 | %/℃ | |

| Kuleylka Gaarka ah | 0.502 | KJ · (Kg ·℃)-1 | |

| Heerkulka Curie | 310 ~ 380 | ℃ | |

| Mechanical Physical Guryaha | Cufnaanta | 7.5-7.80 | g/cm3 |

| Vickers Harness | 650 | Hv | |

| Iska caabinta Korontada | 1.4x10-6 | μQ ·m | |

| Xoog isku dhejisan | 1050 | MPa | |

| Xoogga Jilicsan | 80 | Mpa | |

| Xoog Laabashada | 290 | Mpa | |

| Habdhaqanka kulaylka | 6 ilaa 8.95 | W/m ·K | |

| Modulka dhalinyarada | 160 | GPA | |

| Balaadhinta kulaylka (C⊥) | -1.5 | 10-6/℃-1 | |

| Balaadhinta kulaylka (CII) | 6.5 | 10-6/℃-1 |

Muujinta Sawirka

-

Hordhac Isotropic iyo Anisotropic Ferrite

-

Iibiyeyaasha Jumlada ee Tusaalaha Bilaashka ah ee N52 Block Neod...

-

Sahami Cabbirrada Kala Duwan ee Magnets Ferrite ee xidhan

-

Magnets AlNiCo Tayada Sareysa Ayaa La Heli Karaa

-

Xulasho weyn oo loogu talagalay Neodymium Magnet Awood leh...

-

Codsashada Wareegga NdFeb ee Electroacoustic