Agabka birlabeedka joogtada ah ee Alnico looma qaabayn karo sidii qaybo dhismeed oo ay ugu wacan tahay sifooyinka awooda farsamaysan ee hooseeya, engegnaanta sare, jajabnaanta, iyo mashiinada liidata.Kaliya wax yar shiidi ama EDM ayaa la isticmaali karaa inta lagu jiro farsamaynta, hababka kale sida foornada iyo mashiinada kale lama isticmaali karo.

AlNiCo waxaa inta badan lagu soo saaraa habka wax shubidda.Intaa waxaa dheer, biraha budada ah ayaa sidoo kale loo isticmaali karaa in lagu sameeyo magnets sintered, kaas oo leh waxqabad yar oo hooseeya.Cast AlNiCo waxaa loo habayn karaa cabbirro iyo qaabab kala duwan halka alaabada AlNiCo ee la jeexjeexay ay inta badan yihiin kuwo yaryar.Qaybaha shaqada ee AlNiCo ee sintered waxay leeyihiin dulqaad cabbir ka wanaagsan, sifooyinka birlabku wax yar bay ka hooseeyaan laakiin mashiinnada ayaa ka wanaagsan.

Faa'iidada AlNiCo magnets waa dib u soo noolaansho sare (ilaa 1.35T), laakiin yaraanta ayaa ah in xoogga wax lagu qasbay uu aad u hooseeyo (badanaa wax ka yar 160kA/m), qalooca demagnetization waa mid aan toos ahayn, markaa AlNiCo waa magnet si sahlan loo heli karo. Noqo magnetized iyo sidoo kale si sahlan loo demagnetized.Marka nakhshadeynta wareegga magnetic iyo soo saarista qalabka, fiiro gaar ah waa in la bixiyaa oo magnetka waa in hore loo dejiyaa.Si looga fogaado qayb ka mid ah demagnetization ama qalloocin qaybinta cufnaanta qulqulka magnetic, waxaa si adag loo mamnuucay in lala xiriiro walxo ferromagnetic inta lagu jiro isticmaalka.

Cast AlNiCo magnet joogto ah ayaa leh heerkulka ugu hooseeya ee dib loo rogi karo oo ka mid ah qalabka magnetka joogtada ah, heerkulka shaqadu wuxuu gaari karaa ilaa 525 ° C, iyo heerkulka Curie ilaa 860 ° C, taas oo ah walxaha magnetka joogtada ah ee leh barta Curie ee ugu sareysa.Sababtoo ah xasilloonida heerkulka wanaagsan iyo xasilloonida gabowga, magnets AlNiCo ayaa si fiican loogu dabaqay matoorada, aaladaha, aaladaha korantada, iyo mashiinnada magnetic, iwm.

Liiska Fasalka AlNiCo Magnet

| Darajo) | Maraykan Heerka | Br | Hcb | BH max | Cufnaanta | Isku-dheellitirnaanta heerkulka dib loo celin karo | Isku-dheellitirnaanta heerkulka dib loo celin karo | Heerkulka Curie TC | Heerkulka shaqada ugu badan ee TW | Hadallo | |||

| mT | Gs | KA/m | Oe | KJ/m³ | MGOe | 6.9 | % /℃ | % /℃ | ℃ | ℃ | |||

| LN10 | ALNICO3 | 600 | 6000 | 40 | 500 | 10 | 1.2 | 7.2 | -0.03 | -0.02 | 810 | 450 | Istropic

|

| LNG13 | ALNICO2 | 700 | 7000 | 48 | 600 | 12.8 | 1.6 | 7.3 | -0.03 | +0.02 | 810 | 450 | |

| LNGT18 | ALNICO8 | 580 | 5800 | 100 | 1250 | 18 | 2.2 | 7.3 | -0.025 | +0.02 | 860 | 550 | |

| LNG37 | ALNICO5 | 1200 | 12000 | 48 | 600 | 44 | 4.65 | 7.3 | -0.02 | +0.02 | 850 | 525 | anisotropy |

| LNG40 | ALNICO5 | 1250 | 12500 | 48 | 600 | 40 | 5 | 7.3 | -0.02 | +0.02 | 850 | 525 | |

| LNG44 | ALNICO5 | 1250 | 12500 | 52 | 650 | 37 | 5.5 | 7.3 | -0.02 | +0.02 | 850 | 525 | |

| LNG52 | ALNICO5DG | 1300 | 13000 | 56 | 700 | 52 | 6.5 | 7.3 | -0.02 | +0.02 | 850 | 525 | |

| LNG60 | ALNICO5-7 | 1350 | 13500 | 59 | 740 | 60 | 7.5 | 7.3 | -0.02 | +0.02 | 850 | 525 | |

| LNGT28 | ALNICO6 | 1000 | 10000 | 57.6 | 720 | 28 | 3.5 | 7.3 | -0.02 | +0.03 | 850 | 525 | |

| LNGT36J | ALNICO8HC | 700 | 7000 | 140 | 1750kii | 36 | 4.5 | 7.3 | -0.025 | +0.02 | 860 | 550 | |

| LNGT38 | ALNICO8 | 800 | 8000 | 110 | 1380 | 38 | 4.75 | 7.3 | -0.025 | +0.02 | 860 | 550 | |

| LNGT40 | ALNICO8 | 820 | 8200 | 110 | 1380 | 40 | 5 | 7.3 | -0.025 | +0.02 | 860 | 550 | |

| LNGT60 | ALNICO9 | 950 | 9500 | 110 | 1380 | 60 | 7.5 | 7.3 | -0.025 | +0.02 | 860 | 550 | |

| LNGT72 | ALNICO9 | 1050 | 10500 | 112 | 1400 | 72 | 9 | 7.3 | -0.025 | +0.02 | 860 | 550 | |

| Sifooyinka jirka ee AlNiCo | |

| Halbeegga | AlNiCo |

| Heerkulka Curie(℃) | 760-890 |

| Heerkulka shaqada ee ugu badan (℃) | 450-600 |

| Vickers hardness Hv (MPa) | 520-630 |

| Cufnaanta (g/cm³) | 6.9-7.3 |

| Iska caabin (μΩ ·cm) | 47-54 |

| Isku-dhafka Heerkulka ee Br (%/℃) | 0.025~-0.02 |

| Isku-dhafka heerkulka iHc (%/℃) | 0.01-0.03 |

| Xoog xajin (N/mm) | <100 |

| Xoog jebinta leexleexa (N/mm) | 300 |

Codsiga

AlNiCo magnets waxay leeyihiin waxqabad deggan iyo tayo aad u wanaagsan.Inta badan waxaa loo isticmaalaa mitirka biyaha, dareemayaasha, tuubooyinka elektiroonigga ah, tuubooyinka mowjadaha safarka, radar, qaybaha nuugista, xadhkaha iyo xadhkaha, matoorada, relays, qalabka xakamaynta, koronto-dhaliyeyaasha, jigjiga, qaataha, telefoonada, furayaasha cawsduur, kuwa ku hadla, qalabka gacanta, sayniska iyo agabka waxbarashada, iwm.

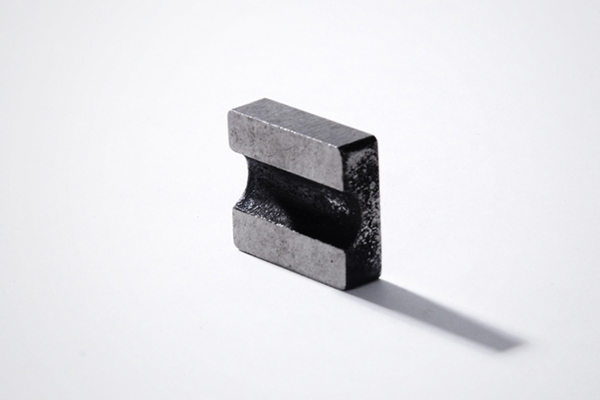

Muujinta Sawirka